Article: First Two Chapters. USSA - Tool Company.

First Two Chapters. USSA - Tool Company.

PROJECTS WE HAVE BEEN WORKING ON:

DESIGN DEVELOPMENT

1 - ZENITH - Quick Release Vise

2024.11 - Today

3D Printed Prototypes - Aluminum Prototypes - ...

DETAILS

YOUR FEEDBACK NEEDED!

When we built Pioneer, our goal was simple: make the best tool we possibly could. We packed it with every feature we could think of. But the downside was the price — many of you wanted it, but not everyone could afford it. That’s why we later made a full range of versions, from budget-friendly to high-end, ending up with 4 options in total.

We want to take the same approach with the Zenith vise. The current vise we’re building is basically the “pro” model — big, heavy-duty, two threads, wide spacing. But the question is: do we stop there? Or do we also make lighter versions?

We already have a plan for a simple one-thread model with two guides — more like a classic vise. But should there be a middle ground too? For example, a mini two-thread vise, same design language, just tighter spacing (200–300mm/10 inches instead of 500mm/20 inches).

That’s the decision we’re trying to make now. What do you think — do we build just the pro and the basic, or should there also be a “mini pro” in between? And what size would you want ideally?

Don't miss the Kickstarter LAUNCH!

ARCHIVE

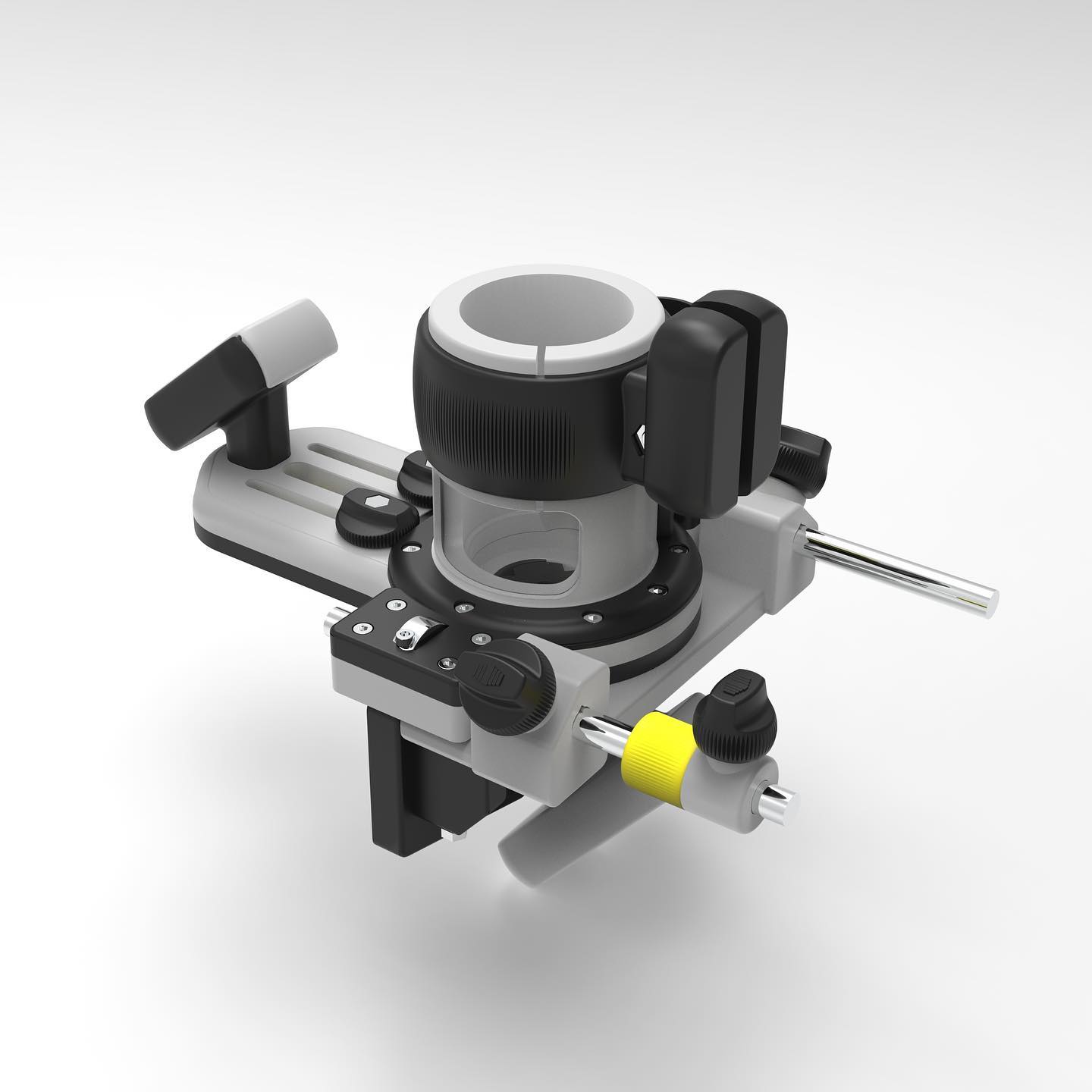

2 - ODYSSEY - The Ultimate Router Lift

2025.02 - Today

3D Printed Prototypes - Launch of a 3D Printable Digital Product - Metal Prototypes - ...

Another product in our library is the Odyssey router lift. It started out a long time ago as an idea. First, we made a 3D-printable Router Lift 3.0. Then, while trying to upgrade it, an entirely new lift was born – the ROM. Building the ROM gave us the experience we needed to take things further and begin the full manufacturing journey.

Now we’re in the final stages of bringing Odyssey to life. But here’s the truth: this one is more of a personal passion project than a commercial product. It turned out to be extremely expensive to produce, and we actually lose money on it. That’s why we’re only making 100 pieces. Limited edition.

Just like with the Pioneer router jig, we’re not stopping here. Odyssey is our high-end model, but we’re already planning lighter, more affordable versions. Early next year, we’ll launch a Kickstarter for them, it's going to be a lighter Odyssey model and lift for big routers—so if you want to follow along, please subscribe. If you have any requests or ideas about router lifts, please don't hesitate to share!

And if Odyssey feels like too much for your work right now, here’s the link to our ROM and ROM-Pro models.

DETAILS

ARCHIVE

3 - "Pioneer" Variations

2025.03 - 2025.08

3D Printed Prototypes - Launch of a 3D Printable Digital Product - Polycarbonate+Aluminum Prototypes - Packaging+Manual Design - Launch

From Prototype to Perfection

Everything we build starts with prototypes — and 3D printing plays a huge role in our workflow. What once took weeks with traditional manufacturing can now be tested in hours, sometimes even minutes. This speed allows us to refine, adjust, and improve until every detail meets our standards — and yours. Even with these tools, each project still takes weeks of design and testing, because our mission is simple: deliver the best product possible. After creating the most advanced trim router jig, our next challenge was to make it lighter, simpler, and more affordable — without compromise. Polycarbonate parts required costly molds, so 3D printing helped us validate every detail before investing in final production.

The prototypes were so strong that we even released digital version for sale, while continuing to push forward with metal variations.

We ordered the next prototypes using final materials: aluminum and resin instead of PC. This method (SLS or SLA) is still cheaper than making a mold, yet more precise than the FDM printing we normally use. It also better mimics the transparency of PC, something FDM cannot achieve. Of course, not everything can be predicted in advance, so some issues still appear in the metal prototypes. This stage takes the longest, with multiple back-and-forth refinements to resolve every detail before approving the final design and quality standard.

TIPS

Tip 1 – Visual Testing Before Committing to a Mold

Before spending big on an expensive metal mold for polycarbonate parts, you can get almost the same insights with a much cheaper approach. For visual results, order an SLA resin print. It will show you almost exactly how the final molded part will look, at just a fraction of the cost of tooling.

Tip 2 – Strength Testing Without a Mold

To test strength, buy a stock polycarbonate sheet or panel and mill it into the shape you need. This gives you a reliable idea of how tough the part will be. In our case, both tests gave us confidence, but when we finally produced parts from an actual mold, we were surprised—the molded piece turned out even stronger than the milled one.

Designing for Affordability

Once the product reaches its final form, we shift our focus to packaging and user manuals. Because our mission with these new variations was to make them more affordable, the biggest compromise had to be packaging.

Instead of EVA foam cases, we developed custom PE foam tailored to each variation. To keep everything secure, we also designed custom cardboard boxes for every model.

THE LAUNCH!

And then comes the Launch! To celebrate, we’re offering our biggest launch discount for one week only. Until 24th of August. We would love to hear from you—please share your feedback in the comments or email us your thoughts and concerns. Every step we take is driven by our commitment to making the very best products possible for you.

DETAILS

ARCHIVE

You can notice, that there are still no holes on these prototypes. After your feedback we decided to keep the previous pattern for 15+ routers, thank you for that!

You can notice, that there are still no holes on these prototypes. After your feedback we decided to keep the previous pattern for 15+ routers, thank you for that!

3.1 - Multifunctional Edge Guide with Micro-Adjustment

2025.05 - 2025.06

3D Printed Prototypes - Aluminum Prototypes - Packaging+Manual Design - Launch

You asked for a bigger Edge Guide with Micro-Adjustment—and we made it happen! This tool now features ultra-precise micro-adjustment for the tiniest milling changes, built tough from 6082 aluminum for performance that lasts. But getting here wasn’t easy. Before we ever touched the final metal, countless prototypes were 3D-printed, tested, refined, and even re-machined in metal. After all that, this week we finally start shipping these Edge Guides—and we can’t wait to hear what you think.

DETAILS

3.2 - 360° Pioneer Router Plate

2024.03 - 2025.06

3D Printed Prototypes - Aluminum+POM Prototypes - Packaging+Manual Design - Launch

You helped shape our 360° Router Plate. When we asked whether you’d prefer to drill your own holes or have a universal plate ready to go, the response was clear—you wanted universal. So we listened. The result is a hassle-free plate with a 360° rotation, designed to keep the vacuum hose out of your way while you cut perfect circles. From feedback to final product, this one was built together.

DETAILS

3.3 - 3D Printable Attachments For "Pioneers"

2025.03 - 2025.06

3D Printed Prototypes - Finalized 3D Prints - Manual Design - Launch

WE DIDN'T FORGET OUR ROOTS

Even though the company is moving towards all-metal products, weight, transportation, material expenses are still limiting the pace of delivering the product onto market and limit it's affordability, that's why we have developed a huge 3d library for pioneer attachments.

FINALIZING

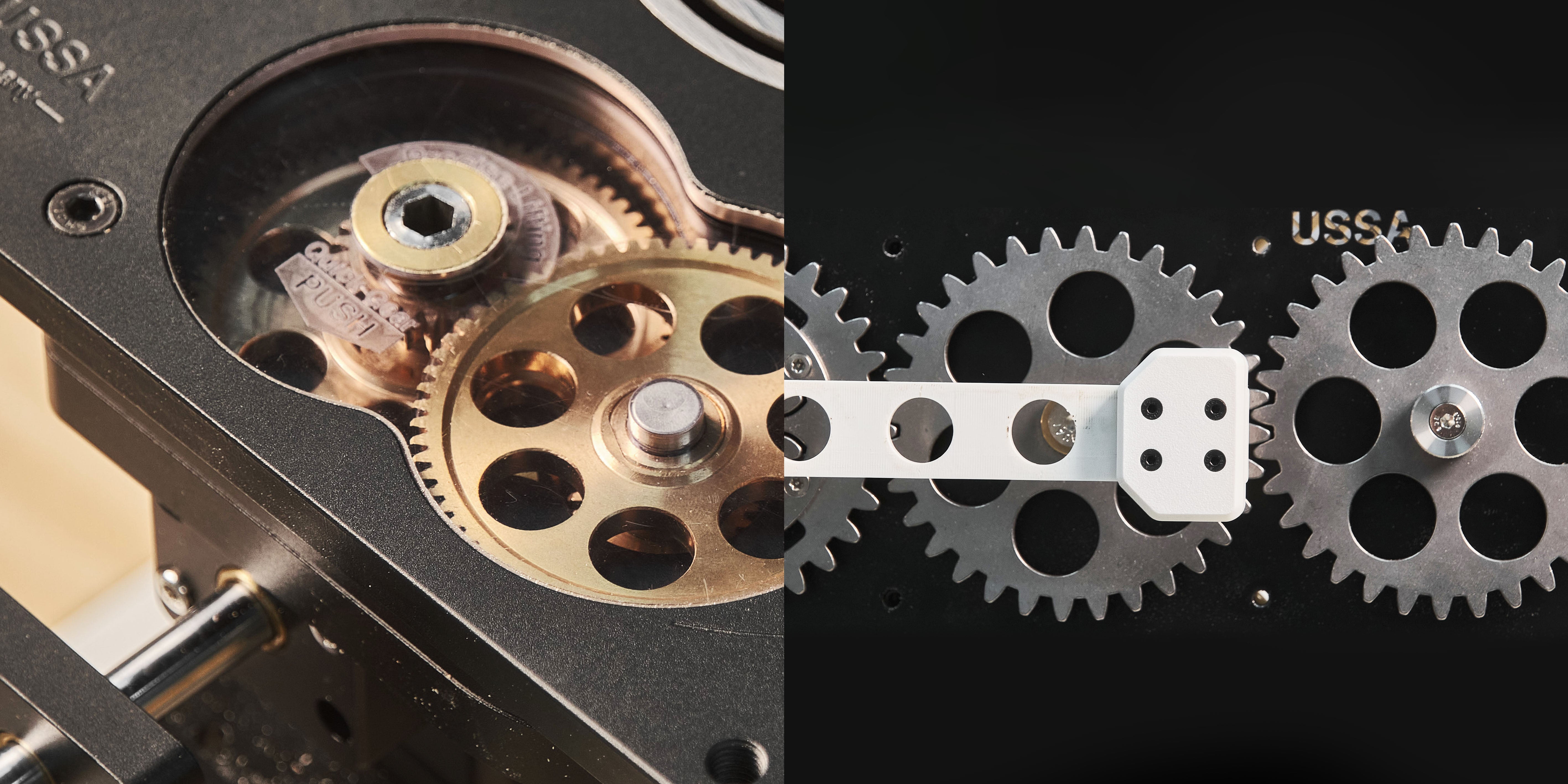

4 - MACHINING

4 - MACHINING

Leveling Up Manufacturing

1. This year, we stepped up our game. We made a mold for the main Pioneer body—a big deal given how complex the piece is.

2. We started using stock parts like washers, gears, and bushings in our designs.

3. Some projects got new material options, like brass and 304 stainless steel in Odyssey and Zenith.

4. We also began making the complex gears for the Odyssey lift and used advanced laser cutting for Zenith parts. Every step is about testing, refining, and pushing our production further.

5 - ASSEMBLY

5 - ASSEMBLY

Thanks to expansion of the team, some assembly was made in-house. For example our new 360° router housing plate and multifunctional edge guide were assembled and packed in-house.

A Big Move Forward

One of the biggest updates is that we’ve moved out of the apartment and into a proper studio. This upgrade gives us the space to scale—what used to be a hundred sets of PE foam is now thousands, ready for the new Pioneer variants.

The studio also made it possible to invest in serious equipment, like an industrial-grade laser engraver and a powered arm drill. From now on, all engraving will be done in-house, speeding up production and helping lower the final price.

6 - PACKAGING

The project doesn't stop after the final design approval, packaging and manual instruction design are yet to be made. All tools require separate manuals and packaging solutions. Here is what needs to be designed for each product:

- Custom box or standard box with a custom sticker

- Custom PE foam set

- Instruction manual

First impressions matter, that's why we designed custom PE foam packaging, opposed to a bubble wrap, so opening it feels just as good as using it.

The Packaging Trade-Off

Since our mission was to make these new pioneer variations more affordable, the biggest compromise was packaging. We replaced the EVA foam case with custom PE foam tailored to each variation.

P.S.

This was all possible thanks to your feedback and support. We managed to move from an apartment to a bigger studio. Our team has grown to 3 people. There has been almost no advertising recently made by us, email campaigns helped us focus on product development and manufacturing, again, thank you all for your support and feedback!

P.P.S

New tools coming up:

These tools get better with your input. Tell us what you think!

1. Doveltron. Currently we have 3 working options.

2. MFT accessories. Retractable and self-tightening doges.

3. Jig dedicated for circle milling for plunge routers.